Waterjet Cutting

Our water jet CNC cutter is great for metals, stone and many more materials, providing a smooth cut edge on very thick materials. We can cut panels up to 2440 × 1220mm from DXF files. Waterjet is brilliant for cutting unusual materials as well as all these listed:

Materials we cut on our waterjet, ‘Winnie’:

Metals

We waterjet cut all metals up to 150mm thick: aluminium, brass, stainless steel, carbon steel, copper, titanium, zinc, bronze, alloys, sterling silver, corten steel

Fabric / Materials

Leathers can be waterjet cut without the burn marks that laser can leave, plus we can cut kevlar, teflon, carpet, rubber and many other materials

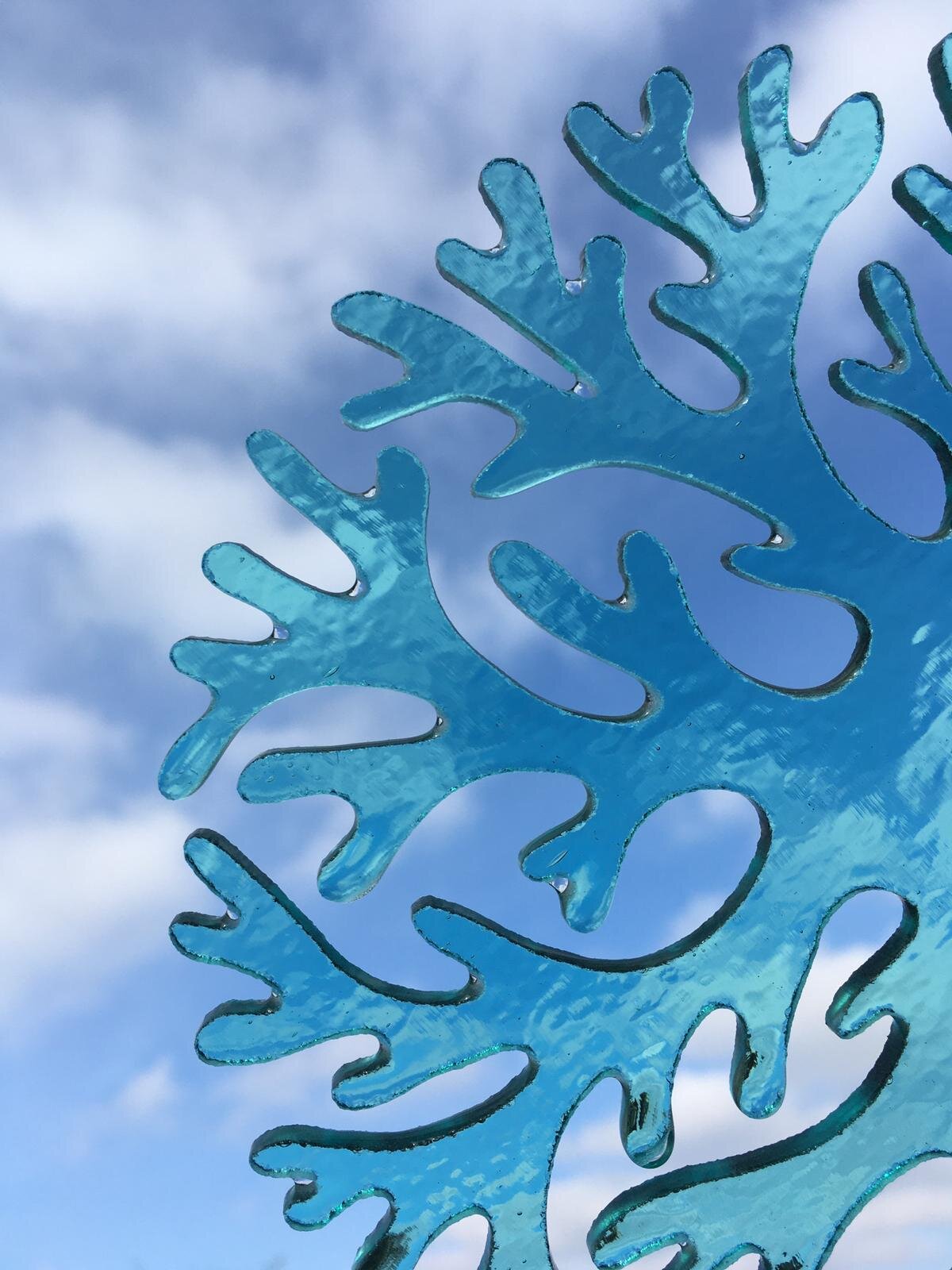

Marble, Stone & Glass

We waterjet all sorts of stone - ceramic tiles, granite, marble, resin, terrazzo, concrete, precious stones, kitchen worktops plus glass can also be cut

Plastics & Composites

We can cut PVC and other plastics that laser can’t such as carbon fibre, fibreglass, foam, linoleum and polycarbonate, plus dibond & multisheild composite sheets as well

Wood

The waterjet will easily manage exterior-grade plywoods and hardwoods that can’t be cut by laser due, with sharper internal corners than CNC router

Anything Else

We absolutely love a challenge - try us! Waterjets can cut practically anything; they’re even used to cut sandwiches in half, but we tend to leave that up to the food factories!

Benefits to waterjet:

Cold cutting method - no heat affected zones that you get with laser cut metal

Nesting capabilities

Small cutting head - 0.7mm

Environmentally friendly cutting method - no noxious chemicals, gasses or by-products

Cutting up to 150mm thick

Cuts materials that CNC router and laser cannot